Microprocessor control panels type “Intellilevel SLC”, for the control of liquid in surface and horizontal tanks.

Microprocessor control panels type “intellilevel ” SLC allow us to check the level of liquid in the tank at any time. The level transducer that comes with this type of control panel is designed to be immersed in water therefore it is suitable for fixing on a submerged tank. The same system can also be used with surface or mobile tanks.

The control panels of type SLC are designed to command diesel oil supply pumps in mobile distributors. These types of control panels have a precision of ± 1% and also have the possibility to set the density of the liquid as required between 0 and 2 y.

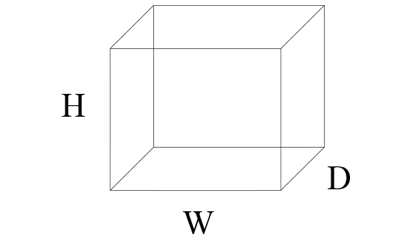

H=250mm W=185mm D=115mm

DIME OF IMPLANTATION H= 142,5mm W= 97,5mm

THE SYSTEM INCLUDES:

- Level transducer type TDL1: included in the price of the control panel, cable length maximum 2mt.

- Electric control panel

THE ELECTRIC CONTROL PANEL INCLUDES

- Plastic box

- Mother card with electronic parts

- Main switch with door lock

- Liquid crystal display showing data and alarms

- Max motor power 1,1 Kw monophase, 4 KW three-phase

- Buttons used for the data setting, gear operating and stopping of the pump

- Possibility to modify the height of the minimum level from 0¸200cm, 0¸350cm or 0¸750 cm

- Possibility to regulate the level of RESERVE and EMPTY from 0¸200cm

- Possibility to regulate the input absorbed from the motor from 0 ¸10A

- Led line, led alarms, led gear pump

OPTIONAL

- Possibility to use alarms from a distance

ALARMS

- Maximum current in the motor

- Sequence or missing phase (only three-phase)

- Tank in reserve

- Tank empty

TECHNICAL INFORMATION

- Tension feed: 230/400V 50/60Hz ± 10%

- Maximun height of the liquid: mt.2, 3,5mt, 7,5mt depending on the type Of transducer used

- Level indicator in cm with decimal point

- Length of the transducer cable: mt.1,8 with the possibility to request a different length up to a maximum of 50mt

- Free potential contact 250V/5A to show at a distance the alarm sounded

- Precision: ± 1% F.S.

- Linearity: 0,2% in the intermediate values

- Level of protection: IP55

- Working temperature: -25°C/+50°C

- Humidity 50% at temperature of 50°C

VISUALISATIONS

- Level of the liquid in cm and decimal point

- Electrical input from the motor

- Reserve

- Empty

- Volume in litres

- Display of the sequence or missing phases (only three-phase)

TECHNICAL DATA OF THE CONTROL PANELS TYPES Intellilevel SLC/M, SLC/T, SLC/C/M, SLC/C/T SLC1 AND SLC1/C

- Tension feed 230/400V. 50/60Hz. ± 10%

- Maximum height of the liquid depends on the type of level transducer used; 2mt., 3,5mt, 7,5mt

- Indication of liquid level in cm with decimal point

- Free contact potential 250V/5A to see from a distance the cumulative alarms (optional)

- Level of protection IP55

- Working temperature –25°C / 50°C

- Relative humidity 50% at a temperature of 50°C

- Maximum length of the cable from the transducer to the control panel 50mt

Intellilevel SLC models

| CONTROL PANEL TYPE | MAX. POWER TO 230V. MONOPHASE | MAX. POWER TO V.230 TRIPHASE | MAX. POWER TO V.400 TRIPHASE | MAX. CURRENT ADJUSTABLE |

DIMENSIONS IN mm | |||||

|---|---|---|---|---|---|---|---|---|---|---|

| KW | HP | KW | HP | KW | HP | H | W | D | ||

| CDL1 | 1.1 | 1.5 | 2.2 | 3 | 4 | 5.5 | 25A | 240 | 180 | 115 |

| CDL2 | 5A | 110 | 150 | 75 | ||||||

| SLC/M | 1.1 | 1.5 | 25A | 240 | 180 | 115 | ||||

| SLC/T | 2.2 | 3 | 4 | 5.5 | 25A | 240 | 180 | 115 | ||

| ALC/C/M | 1.1 | 1.5 | 25A | 240 | 180 | 115 | ||||

| SLC/C/T | 2.2 | 3 | 25A | 240 | 180 | 115 | ||||

| SLC1 | 5A | 110 | 150 | 75 | ||||||

| SLC1/C | 5A | 110 | 150 | 75 | ||||||

RELATED PRODUCTS